Everyday Empires: Cody Howard’s Rowdee

How Cody vetted 200+ manufacturers to create technical apparel that hits the town just as well as it does the trails

Hey folks,

Welcome back to Everyday Empires, where I chat with everyday people building ventures that transform their lives.

Today, I’m sharing the story of Cody Howard and his venture, Rowdee.

Cody had an idea he couldn’t get out of his head. As an avid outdoorsman, he wanted a shirt he could wear both on the trail and around town. When he couldn’t find anything on the market that fit the bill, he decided to make it himself.

As someone who is rather active outdoors myself, and who loves to spitball technical apparel ideas (don’t we all?!), I was curious to get the scoop and learn what it took for Cody to go from just an idea, to a real physical product and a brand people are raving about. So I did what we do here at Everyday Empires and emailed Cody to find out!

In our interview, Cody shared:

The first steps he took to turn his idea into an actual business

How he emailed and vetted 200+ manufacturers before finding the one

How he used a combo of paid ads & an in-person event to get his first customers

The advice he wish he knew when he was starting

And here’s what stands out about Cody’s story:

Like many founders I’ve chatted with, Cody designed a product to solve a problem he was personally experiencing and understood well

In the first 6 months he studied existing garments, and validated the need for the product by talking to mountain biking friends who had no idea he was up to something

He emailed 200+ manufacturers! That is wild to me and shows how much he cared about finding the right manufacturer. It also sounds like a lot of work, and is good to know this is what it might take to launch something like this

He’s embedded in the mountain biking community, and took a grassroots approach to launching his brand, which seems to have been critical in getting early traction

Now, let’s get to the interview (10 min read) …

Founding Story & Inspiration

Can you give us an elevator pitch for Rowdee? Who’s it for and what problem does it solve?

Cody: If you look around your closet today, you’d probably notice a few things. Yes, you should clean up the pile of dirty clothes on the floor, but you’ll also notice a number of items made only for specific events or activities. Most of these items you probably only wear a few times a year, but life isn’t like that. Your life is fluid; plans change with a text. Your perfect Saturday may include a hike, straight to coffee with friends, and a lunch date to follow. Your clothes can’t adapt like that, and if we’re being honest, that kind of pissed us off.

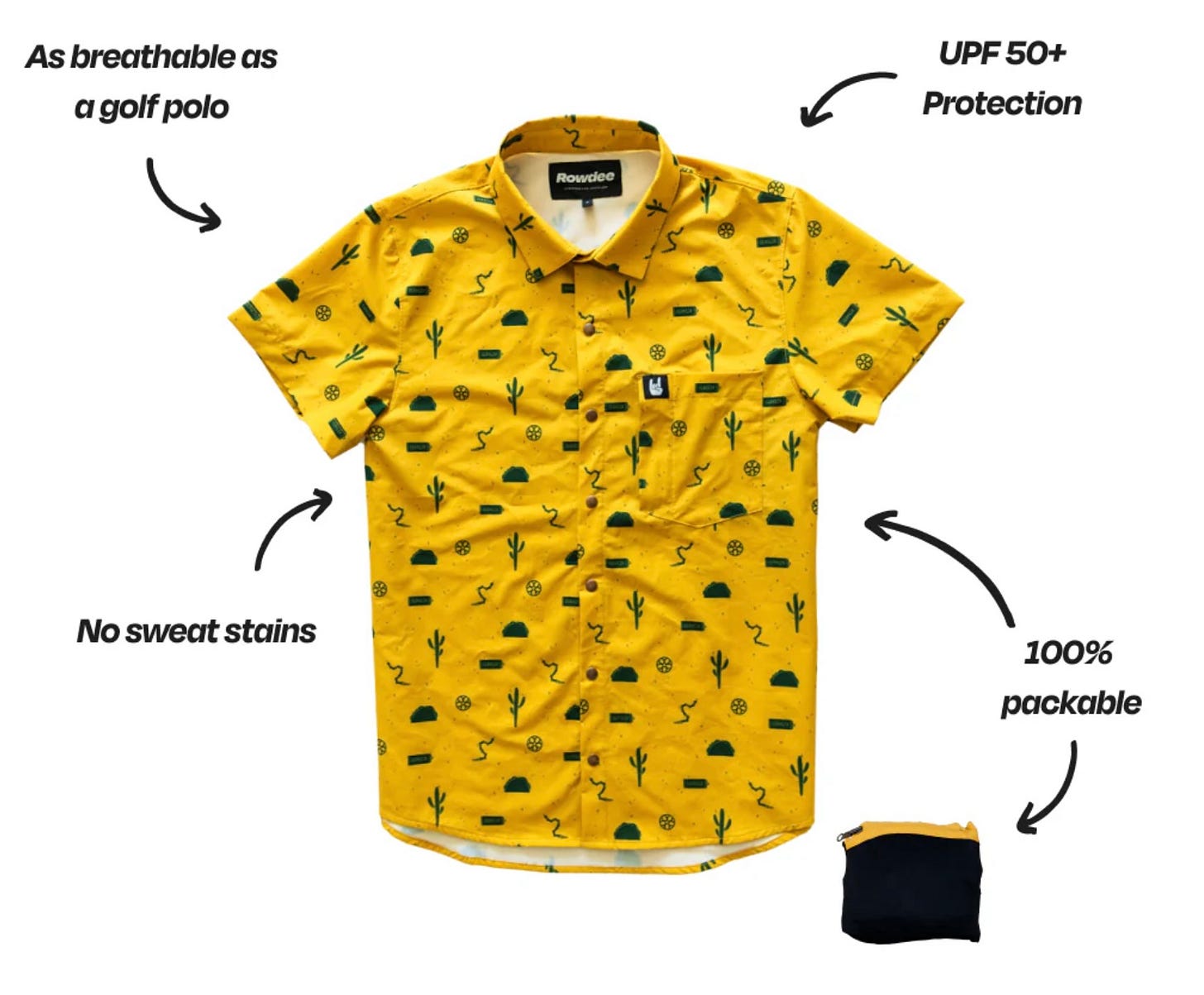

That’s why we created the Shindig Shirt, a shirt that looks at home in the office or at happy hour, but has the hidden tech to handle everything your active lifestyle may throw at it. From office to out of service, golf to grabbing a bite, Rowdee makes clothing for men that is as adaptable as your weekend plans. Now you can spend a little less time worrying about what to wear and more time living.

How’d the idea come about, and why’d you decide to actually pursue it?

Cody: I live in Boise, ID, a city that features 150+ miles of connected trails just 10 minutes from downtown. There is a river running through downtown that is constantly filled with fly fisherman or people floating. An hour north is world class whitewater rafting and 20 minutes east is Lucky Peak Reservoir.

To say that most people juggle 3-5 outdoor hobbies is an understatement, and I am one of them. Most of the time those activities end on a patio with a few drinks. One of those afternoons, I looked around and noticed that most of the patio was filled with people who were dressed well and clearly meeting for lunch… and then there was my motley crew wearing a mix of tech tees, jerseys, and skin tight lycra… when they didn’t necessarily have the body to be rocking skin tight lycra.

I thought to myself, man. It would be great if I could show up to a post-ride lunch without everyone around knowing that I had just been out on the trail. No packing an extra shirt, just something that could work in both places. But I had just gotten comfortable in my new job and absolutely loved (still do) the team that I was working with so I let it go. A few weeks went by and it was still on my mind. A few months went by and I shared the idea with my wife and then we started to see some similar products hit the market. Finally, I decided that the worst that could happen is I lose some money but gain valuable experience, so I went for it.

I understand it took 18 months working through the details to produce your first product, the Shindig shirt. What gave you the confidence to put in all this energy up front? Did you have any doubts along the way?

Cody: It was the perfect mix of ambition and naivety that kept me moving forward. As an avid outdoor enthusiast, I’m also part of the target market, so I knew of a few companies that were making similar products. I made note of what I liked about them, what I didn’t like about them, and what could be improved. I only told three people during the first 6 months, which gave me ample opportunity to ask these same questions to friends who weren’t aware of my secret agenda.

I only told three people during the first 6 months, which gave me ample opportunity to ask these same questions to friends who weren’t aware of my secret agenda.

When all of the answers seemed to match, I knew I was on to something that could really work. Then came the excitement of the prototyping process. It took months to figure out a fabric blend that was sustainably made and durable enough for the outdoors. Once that was set we moved into evaluating the fit, patterns and tech. Each prototype kept me motivated despite multiple delays and refinements. This led to the long 18 months of R&D which was vital to the success that we’ve seen in our first months. It’s a top tier product with a great price point, making it inherently shareable and leading to many referrals and repeat buyers.

The Shindig shirt is technical enough for the trail, yet casual enough for life. It’s breathable, wrinkle-resistant, UPF50+, packs into its own pocket, and comes in great patterns. For those of us who have no idea what it takes to design a product like this, can you walk us through the process? Was it as simple as a sketch? Did you have it all figured out from the beginning or did it evolve as you got into it? Did you collaborate with any experts?

Cody: This is a great question, because I had no idea what all went into this either before I began the process myself. I started with a simple sketch and a list of non-negotiables. Such as: no sweat stains, UPF protection, stretch for activity, and sustainably made. From there I researched everything I could to find out what went into it. I learned about tech packs, which is essentially a blueprint of the garment. I studied fabrics and fabric blends and filled my camera roll with the inside tags of shirts. Rather than taking an out of the box product and slapping a logo on it, I chose the hard path of building from the ground up.

This meant that I had to do a lot of research and make special requests to get the quality grade materials that I envisioned for our product. Paying way too much money for a sheet of buttons or a bundle of zippers to be mailed to me and losing sleep over details that very few customers will ever notice were some of the hoops I jumped through to make the Shindig Shirt. This is what makes the shirt a standout—great design is invisible, it’s only when it’s done poorly that people tend to notice.

Everything in our shirts from the OEKO TEX seal fabric, UPF ratings, snap buttons, zippers, woven tags, and designs were either created by me or hand selected in partnership with our factory.

You’re using a manufacturer in Peru. Can you share why you chose them, and how you found them?

Cody: In the early days I think I cold called or emailed 200+ factories. From there it was about finding factories that had small MOQs. We needed to start small because I’m bootstrapping the business. Then it became a battle of what we wanted for our product. Most factories didn’t have the full capabilities of what we needed. They could do four way stretch materials, but not collars. Or they handled collars, but their machinery couldn’t handle the warp of stretched materials. After getting a list of factories who thought they could make what we had put in the tech pack, we got samples. Some were hilariously bad and a few were pretty good. So we refined and got another smaller round made.

Ultimately, we chose our factory partner because they were the highest quality and delivered the most detail with each sample. This was a sign that we could likely have a collaborative partnership and I’ve been happy to say that it has been to date. Personally, I’d love to have a US factory someday, but it’s just not possible for us at this stage.

Initial Momentum & Decisions

How’d you get your first customers? Where has most growth come from since?

Cody: Outside of friends and family, there were a few things that we did that helped kickstart our first sales.

First, I decided to launch pre-orders shortly after starting production. I got help from a friend and great photographer to shoot our initial website pieces and ads. I spun up some small budget meta campaigns and started getting a little traction.

The second was getting an opportunity to have a booth at the Boise MTN Bike Festival. We got offered a spot about two weeks before the event so I rush-ordered a custom booth, backdrop, and we considered it our “launch party.” All we had were samples, some t-shirts, a few hats, and a ton of koozies that we handed out. It was one of the best experiences I’ve ever had.

To share our story and have people put in an order for a product that they won’t get for months was amazing. For that reason, I love in person events and hope to grow that presence in the future.

I noticed you’re making a lot of short form video content (and are quite good at it). How does this fit into your growth strategy?

Cody: Thank you! I really appreciate that. I’ve always loved video and I lead content strategy at my 9-5, so it’s fun to be able to stretch those muscles for the brand. I’d love to be putting out 10x more content, but simply don’t have the time.

Content in general has and will continue to be a cornerstone of the Rowdee brand. As a bootstrapped company, we don’t have the capital backing or ad budgets that most of our competitors have, so storytelling has to be our superpower. If we can create content that invites you into being part of our community and aligns with your lifestyle, then receiving a stellar product when you finally order will be a huge cherry on top. My hope is that it will turn you into a brand evangelist who is excited to share the product with their friends.

While short form is an amazing opportunity for anyone who is not familiar with content creation, I’m actually trying to crack the longform code and am bullish on our YouTube channel being the future of Rowdee.

I love this stuff and could write an essay around this question alone so if anyone wants to chop it up or is also focusing on YouTube - you know where to find me.

I believe you’re running Rowdee on your nights and weekends, while working a 9-5. Can you give us an idea of the day-to-day for you and how you make time for it all? Are you still able to get out on the trails?

Cody: Ha! I wish. I still get out on the trails as much as possible, but about 10 months into the prototyping process we found out that my wife was pregnant with our first child, Theo. Let me tell ya, building a business and having your first child within the same year makes for very little sleep and a very necessary coffee subscription. It’s been the best whirlwind and a season that I’ll never forget, so thankful for all of it… but it does make for long days.

I am still working at an award winning advertising agency as the Director of Digital and running Rowdee simultaneously. I am thankful to be able to do both. My position at the agency has afforded me both patience and perspective. Because I didn’t jump “all in” on Rowdee day one, I was able to last the 18 months to roll out our first products without cutting corners. Though Rowdee is much smaller than the typical brands we work with, it’s also given me perspective on what signals to pay attention to.

Do you have any key financial metrics, customer feedback, or other indicators of performance you’re comfortable sharing with us?

Cody: Having financial strains have actually helped us listen to the customer and make a better end product. We could afford three designs so we had to cut our launch to only two shirts and a few weeks after delivering all pre-orders we noticed that we were getting a lot of size exchanges for L, XL, and XXL sizes to size up. After speaking with some customers we found out that as our pattern went up in size most men needed some extra width across the chest and shoulders after hitting these size breaks.

It taught us that our product was great. Everyone seemed to love it, they just needed a bigger size. It also taught us the importance of starting small. Because we were able to find that out with only two styles we adjusted our pattern and have since released all new designs as a “relaxed fit” that has cut our returns and exchanges to below 8% (clothing industry average is 26%).

Insights & Reflections

If you could go back to the very beginning days of Rowdee, what advice would you give yourself?

Cody: That’s a great question. I would tell myself to spend less time researching and planning and more time doing. My typical pattern can end up in a hamster wheel of thinking about things and researching nonstop that I’m burnt out before I even begin the real work. While research has its place, I’m trying to remember that everyone is just trying to figure it out and the best thing we can do is take action with the goal of learning enough to know where to pivot.

Fail fast, fail often.

How has your experience with Rowdee changed you?

Cody: The last few years of getting started and almost 12 months of being in market have changed me more than I even know, but in one major way it has made me a more thankful person. Until you build something, you don’t really understand everything that goes into a quality product. From the product to the materials to the hands that crafted those materials, I’ve realized that Rowdee has been my own Thanks a Thousand journey.

Lastly, where should readers follow you and Rowdee?

For anyone that wants to keep up on our bootstrapping journey or just digs rad videos about the outdoors check us out on YouTube and Instagram.

If you’re another founder or entrepreneur, I periodically share BTS and caffeinated takes on building a brand at @rowdeehowee on X and @rowdeehowee on Instagram. If you’re reading this, hit me up. I’d love to connect with you.

That’s a wrap

A massive thank you to Cody for sharing his time with us! If you enjoyed this, you can support Everyday Empires by taking a moment to:

❤️ Like this post to get it in front of more future founders

💬 Reply or comment to share your thoughts or ask a follow up question

📤 Forward this post to someone who’d benefit from it

You might also like these interviews:

See y’all next time,

Ken